Environmentally sustainable battery production in the Horizon Europe work programme

22 November 2022

The 2021 Batt4EU Work programme includes a call for proposals to build on the pilot line research which has been done within the context of LiPLanet

Manufacturing of lithium-ion batteries is currently facing key challenges, among which ensuring they are environmentally sustainable. The 2021 Batt4EU Work programme included a call for proposals that would build on the pilot line research which has been done within the context of LiPLanet: the call expects the project to mark Europe as a distinguished player for sustainable battery manufacturing, and as such, the EU foresees to contribute with 20M EUR for 4 projects. The technological level targeted is TRL 5-6, signaling that the solutions will reach the demonstration phase at the end of the project and will be eligible for further uptake activities, either through another Innovation Action within Horizon Europe, or through other European funding channels such as European Innovation Fund.

One of the main objectives of this call is the sustainability of electrode production. Removing the use of Volatile Organic Compounds (VOC), such as N-methylpyrrolidone (NMP), is consequential on carbon footprint levels of cell manufacturing. Although widely known as the dominant technology for preparation of the electrode slurry, the recovery of VOC s during drying process are costly and energy- intensive.

There are two main alternatives to electrode processing with VOCs, water-based and dry: the former simply substitutes NMP with water, making the process significantly cheaper and safer. However, the adaption is hurdled by the quality of the electrode produced by this method; for example, formation of lithium compounds on Ni-rich cathodes due to residual moisture. The slurry solution might not meet the expected rheological properties (resulting in unwanted scrap rates in further steps), and the electrodes resistance increase due to inhomogeneous distribution of conductive network.

The second technological innovation is dry processing of the electrodes. As the name suggests, the technique can potentially eliminate the drying process, which can result in 30-35% and 10% lower energy consumption and production cost, respectively. Facing with similar challenges to the water-based process in terms of conductivity, this method also imposes the problems with probable compromised environmental footprint and electrode properties during dry mixing and coating. However, the dry electrodes provide the possibility of adapting the rapidly growing technology of 3D patterning, an approach that will have significant cost benefits and improve the cell quality by limiting the randomness of the electrode structure and properties after drying.

Dry manufacturing also enables the implementation of hydrophobic surface treatment of electrodes, paving the way for next generation materials such as high-voltage Ni-rich cathodes and lithium-metal anodes.

Projects are, furthermore, asked to address other concepts within their scope: the ability to integrate the findings into digitally-driven larger production lines; proposals of technical solutions to ensure workers and users safety; and, investment in a “Design to Manufacture” approach, the latter being crucial considering the ambitious EU battery goals – which imply that a huge part of applications need specific batteries. On the other hand, a large number of chemistries are standing behind the starting line, ready to debut on the market in the upcoming years. There put emphasis on the need to minimize production, as well as environmental costs of disconnected design-to-production procedure.

Once completed, this idea can enforce the European battery manufacturers leverage. One of the concerns of OEMs in their transition to electromobility is the adaptability of cells to the diversity of their products. Growth in the non-European market supply and their manufacturing maturity already signals low profit margins for competitors. Therefore, the extra cost of production-oriented re-designing should be treated as an unnecessary burden.

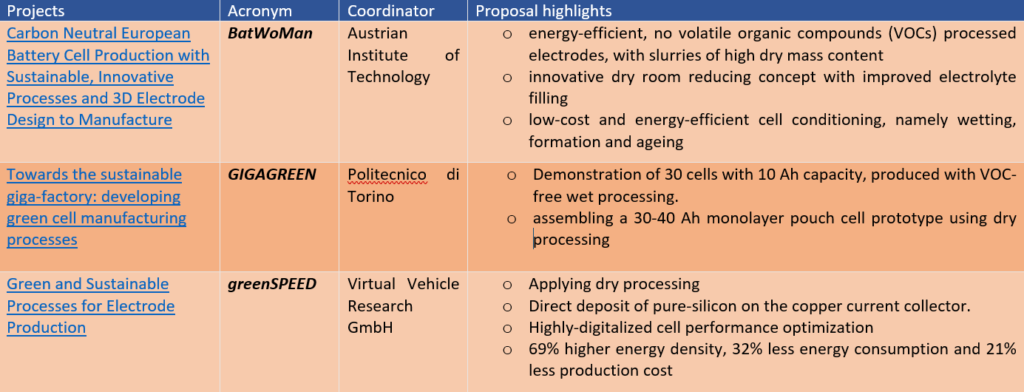

The following projects are selected by the EU commission to tackle these challenges and be part of the collective research activities aiming for a circular and sustainable European battery value chain.