Resource-efficient batteries: sparking sustainable e-mobility with improved batteries

23 February 2023

Surging demand for batteries poses significant challenges for battery manufacturers: what is the future of battery technologies to keep up the pace with growth?

The European battery production landscape is expected to boom – to say the least – within the framework of the announced projects of over 1TWh of capacity until 2030. At the same time, battery demand is experiencing an unprecedented growth which poses significant challenges for OEMs, striving to keep up with this surge. Imbalance between supply and demand, and political turmoil at global stage have already made LIB production sourcing a strategic arena.

Accordingly, common interest rose to promote recent technological improvement in up-scaling of high energy density chemistries, such as solid-state batteries, or to heavily include reliable elements like sodium-based systems in our projections. Despite all these efforts, however, the majority of planned European gigafactories still take into account liquid-electrolyte lithium-ion batteries in short to mid-term.

The broader perspective of net-zero mobility is the flip side of the coin. The entire value chain, will aim to reduce carbon emissions – voluntarily or through the force of stricter regulation. This drive for lower carbon emissions will also affect the battery manufacturing sector. The recently published communication on the Green Deal Industrial Plan states that “across all economy, the clean energy sector is 20% more productive”; but, the unfortunate rise in cost of energy and raw materials might influence this figure in the final regulations.

Developing highly efficient batteries addresses the concerns over the sourcing of materials and the footprint of the value chain. Upgraded output/input figures serve to, firstly, reduce stress on the raw material market, and secondly, to partially fill the void before European mining projects ramp-up to create a local supply chain. In addtion, they will lower the operating costs of energy and reduce the project’s CO2 footprint in the context of a win-win strategy.

Resource-efficiency is measured as the performance of the product for the given amount of input resources (energy, material, labor, etc.). In the battery space of academia and industry, this concept is generally conceived through two main metrics: the amount of energy per weight/volume, and the cost of production per energy content. However, the level of technological capability and the non linearity of battery operation might mean that these metrics are not representative of their sustainable traits.

Several factors contribute to such misrepresentation, namely, divided terminology, generalized clustering of rather independent technologies and systems, subjecting the performance indicators to limited (or single) standardized utilization patterns, and lack of product transparency. These are, amongst others, the reasons why getting a complete picture of an “efficient” battery is difficult.

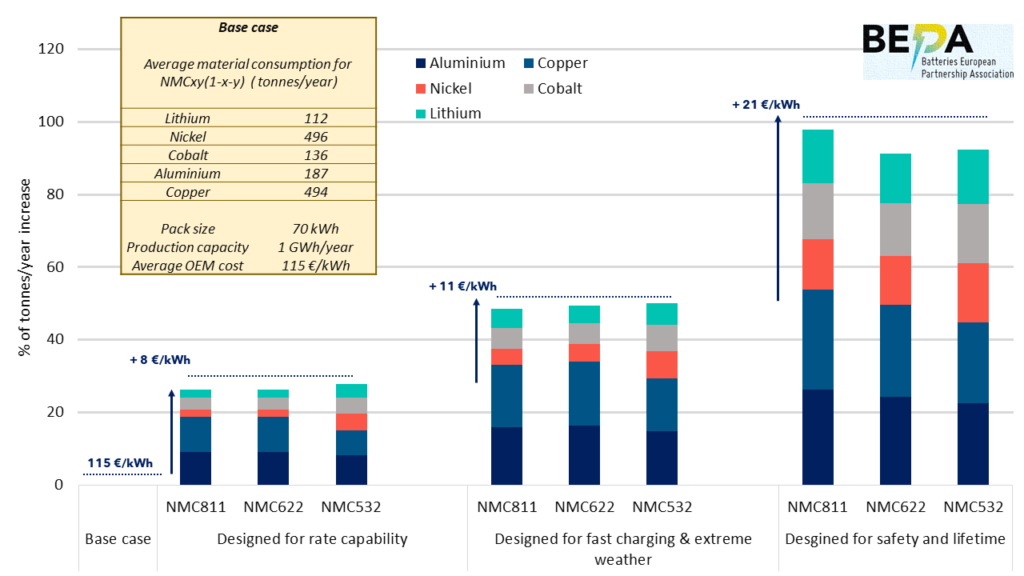

Take for example the modeled cost and material used for a 70 kWh EV battery pack with a performance that is currently the norm of the market. The model shown in Figure 1 tracks how design constraints and performance objectives move the minimum required material and cost from the theoretical values to an oversized system with adapted design. The case is designed for a particular chemistry, NMC/Graphite, to highlight the impact of operating conditions and inherent limitations; hence, differences by employing other cathode materials (e.g., LFP) and improvements through chemistry alternation are excluded.

Figure 1. percentage of increase in annual magnitude of raw materials and corresponding increase in pack cost for each level of requirements and constraints. The values for each step of design adaption represent average figures for a set of alternative designs and scenarios. The applied models can be found in Methodology.

Power duty and theoretical limitations

The theoretical energy of a cell is often expressed as the integral of the voltage over the discharge capacity of the battery at low rates. However, average practical rates of vehicle application (i.e., crate<1) reduce this value to the “practical energy”. On the other hand, in design of lithium-ion batteries for electric vehicles, the maximum intended load (i.e., rated power) is the parameter that determines how much of the practical energy is “accessible” during high target loads. During most of the driving cycle, the practical energy is fully utilized; nevertheless, to avoid reaching cut-off voltages prematurely, extra units are provisioned to equip the system with the promised power capability, while maintaining the promised range. The required extra unit depends on the ratio of rated power to the nominal energy, which depending on the type of vehicle and OEM falls mostly between 2-4.

The optimum design at this stage is the best trade-off between two main competing factors: the design option that prioritizes cost-effectiveness at the cost of high internal resistances and minimizes the number of units to be purchased and processed. (i.e., active materials, electrode sheets, cells, etc.) vs the design that can tolerate high loads at the expense of higher units. In both cases, the extra cost and material (compared to a design based on theoretical values) are inevitable given that the rises in transport limitation in solid and liquid phase are amplified by higher cycling rates.

Extra requirements

The widespread adoption of electric vehicles requires battery packs to maintain their expected performance under variable weather conditions as much as possible. For the same material, keeping the performance integrity of system under extreme conditions impose extra compromises. Fast charging is also gaining rapid attention both among policy makers and within the private sector. Just as rate-limitations, here the challenge is alleviated through increase in the quantity of electrode sheets, the adoption of electrodes with lower loadings, and the integration of smaller cells; all of them ultimately result in a production line that is both materially and financially intensive.

Safety and ageing

So far, the system is set to satisfy the expectations under rated loads, environmental extremes and fast charging. However, as the battery ages, the likelihood of various side reactions becomes more prevalent over time.

This is where a safe margin of capacity can ensure reliability with reduced chance of unexpected events through lowering the nominal intensity of duty. Such margin also serves as a reserved capacity, so the system holds its capabilities throughout the useful lifetime in spite of the inevitable power and energy fade. The common term “usable energy” in EV market refers to this class of extra capacity, that is the content not utilized in the beginning of life, yet will get into circle as the battery degrades. The value is between 5 to 15% depending on the OEM, although extended regulations on obliging manufacturers to release these data is pending.

Range anxiety

The common, although fading, concern among buyers has convinced the OEMs to assemble the packs with sizes that could be considered excessive for many consumption routines, such as for urban costumers. Addressing this concern is not merely a matter of battery energy density, but it requires rapid innovation across other fields coupled with well-represented advocacy, citizen-engagements and policy actions. That includes improvement in charging power electronics, adequate geographical spread of charging infrastructure and options, and incentives for workplace charging.

Addressing the problem: THE role of EU and BATT4EU

Published in January 2023, articles 9 and 10 of proposals for battery regulation provide performance and durability criteria of batteries for mobility applications. The proposal addressed three main performance indicators; rated capacity, power and internal resistance. Whether all these indicators together are satisfactory to provide an accurate tool of measuring the material efficiency, it remains to be seen and discussed.

The efficient utilization of critical minerals and reducing GHG emissions of manufacturing play major roles in achieving the objectives of European Green Deal. Implementation of these objectives within the rapidly growing European battery industry requires constant provisions that are comprehensive of the entire value chain, starting from promoting innovative solution.

Here we introduce a few of main measures that effectively contribute to that cause and are proposed in Batt4EU partnership strategic research areas; Digitalized battery production that embody European visions in advanced manufacturing, safe materials toward establishing a global benchmark of reliability, digital passport products as an imperative tool of transparent and long-term sustainable planning, and establishing a shared ontology for a life cycle inventory for zero-emission vehicles and their battery cells.

Digital twins for monitoring, manufacturing and characterization

Although researchers are able to a large degree to identify the theoretically “perfect” design, and what would be the optimum electrode structure and composition to deliver rated power with minimum content, matching that theory to reality of electrode material properties, and manufacturing inefficiency, remains a challenge. As these discrepancies between the theoretical input and practical output are spread within multiple stages of production, accelerated computation is a key tool for decision making throughout the supply chain.

In order to stay competitive, new-born European gigafactories need a reliable digitalized lean solution to reduce the scrap rates; not only, they also need to curb the avoidable raw materials purchase to boost the time and cost efficiency of increasing production scales.

A standard definition of digital twins is yet to be developed, even outside of the battery value chain. The term is commonly used for various levels of digitalization through all research and operation steps from discovery of new materials to optimization of supply chain, where all of these purposes contribute to declining cost and environmental impact. In manufacturing however, the resolution could also have a substantial effect on the forthcoming shift of workforce from internal combustion engines to electrically powered drivetrains. If tailored and designed properly, the automation focus will be directed to specifically address the possible knowledge and skills gap, paving the way for smooth transition of labor.

Digitalization goes hand in hand with the European Green Deal targets so much so that the Commission speaks of the “twin transitions”. Minimizing the footprint of net-zero transition without maximized adaption of advanced computerization is difficult to imagine. The Batt4EU partnership has incorporated this philosophy into a variety of battery research areas, especially in energy-intensive parts of the value chain, like manufacturing. This is reflected in one of the Batt4EU 2023 topics on digital twin in manufacturing. The topic expects multi-stage consideration of automated perspective, and requires explicit addressing of the product quality and resource efficiency through implemented proposals.

Improved Safety materials

A diverse array of safe materials and solutions exist, and they can effectively address the excess content margin without the need for reinventing the wheel. Such strategies and modifications should be aimed at dealing with material interfaces all the way to thermal management at the system-level. A prime opportunity of improvement in liquid-based LIBs is addressing nearly 10% irreversible loss of cathode capacity by de-lithiation during the formation process. Cathode structuring is another crucial target, given the sustainable low-cobalt cathodes necessitate proper mitigation methods to compensate for the mechanical properties attributed to cobalt content. The 2023 Batt4EU topic aims to limit the margin of error by both improving the cyclability by 15% by 2030, and to use electrolyte formulas that broaden the stable potential window. The topic invites novel methods, like doping and coating strategies for minimized and high-quality SEI and CEI, and micro-level optimized electrode balancing to maximize use of combined high voltage cathode and anode. The proposals will be supportive of implementation of fast charging ideas, as suppressing dendrite formation in high cycling rates can further reduce the inevitability of inefficient design options.

Digital Passport

In addition to key life cycle indicators and mining origins, a battery passport potentially serves as a comprehensive record of the material composition and the corresponding performance characteristics of a system. This affords the public with a valuable insight into the resource-efficiency of a battery pack. To achieve this, it is necessary to implement simplified models that enable the stakeholders to perform requisite computations and assess the true value they receive for their investment.

The global battery alliance has been in the front seat of mobilizing the activities around digital transparency in the battery value chain and has recently launched its proof-of-concept for a battery passport. European R&I activities can take the lead in developing cohesive indicators of sustainability and responsibility and couple them with state-of-art blockchain solutions and real-time monitoring to facilitate the broader deployment of LIBs that ensure the public of their responsible life cycle.

Other activities

Another promising news is the kick-off of the Horizon Europe project TranSensus LCA earlier this year with the coordination of Fraunhofer Institute, that aims to establish a standard LCA methodology. Born from a joint topic between Batt4EU and 2ZERO partnership, the project partners will demonstrate a “single European-wide real-data LCA approach for zero-emission road transport”, and secure the leverage for business models that take optimal material usage seriously.

Lastly, a specialised task force within the open think-thank Batteries Europe, funded under the 2021 Batt4EU Work Programme, will cast light on the social science surrounding the transition to a green economy, and allow for better and broader understanding of societal barriers (like range anxiety) that currently form obstacles towards a better use of the available materials. This will help application manufacturers to create more sustainable products while still adequately fulfilling their costumers’ needs.

Conclusion

Based on the desired vehicle performance, a LIB pack in an EV passes several steps of design and manufacturing adjustments to fulfill customer expectations. Such transformation results in extra material and investments, which could potentially be avoided. How far that potential goes is a persistent topic of debate among researchers and industrial players. This is where the “holy grail” concepts such as solid-state materials provide plausible cases. Nevertheless, the projected commercialization timelines of transformational technologies demand appropriate channeling of strategical focus.

At the moment, one approach by OEMs on these issues is using design alternation and capacity oversize to overcome several layers of limitations, starting from inherent chemical hurdles to ensuring minimum refill time.

The Batt4EU Work Programmes contain several alternative solutions which require explicit research and innovation investment: automated manufacturing, discovery of safe materials, a digital battery passport, a sector-specific LCA methodology, and better cooperation between the battery value chain and the social sciences. Aligned with the broader European rush to climate-neutrality, such concerns are addressed in the Batt4EU partnership agenda in the upcoming year’s research priorities, and will be challenged by almost €40 Mil. of Horizon Europe funding.

Methodology

The Argonne National Laboratory’s BATPAC model is applied to the design, and material usage assessments. The design parameters are, then, used as the input for the process-based cost model developed by Sakti et al. for calculation of the OEM manufacturing cost. Parameters of cost model are based on Sakti et al., and Duffner et al.